Description

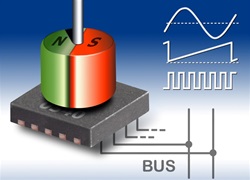

The CMOS device iC-MA consists of a quadruple hall sensor array which has been optimized for the magnetic measurement of angles of rotation. This array permits error-tolerant adjustment of the magnet, reducing assembly effor ts. The integrated signal conditioning unit provides a differential sine/cosine signal at the output. The sensor generates one sine cycle per each full rotation of the magnet, enabling the angle to be clearly determined. At the same time the internal amplitude control unit produces an regulated output amplitude of 2Vpp regardless of variations in the magnetic field strength, supply voltage and temperature. Furthermore, signals are provided which enable the sensor amplitude to be assessed and also report any magnet loss. With the aid of the integrated 8-bit sine/digital converter the angle of rotation is determined from the sine/cosine signals. This is output via an incremental interface in a number of selectable resolutions. The zero angle is indicated by an index pulse. The maximum resolution of 8-bit is maintained up to rotations of 60,000 rpm. The absolute angle of rotation can be conver ted back to a linear analog output signal using the internal D/A converter ; here, output voltage limits can be set as required using the external pins. Either a periodic linear signal (sawtooth) or a delta voltage (triangle) can be provided. iC-MA can be easily cascaded in three different modes of chain operation so that several axes of rotation can be scanned. The angle positions of the individual axes can then be read via a common bus. Used in conjunction with a permanent magnet iCMA can act as an encoder system with an integrated magnetic scanning feature. No fur ther components are required.

Features